The perfect result for a crop of maize silage is a green plant and full starch. In practice this is not easy to achieve as in a lot of crops the plant begins to dry down before full starch is reached in the maize kernels, due to a number of factors often linked to lack of moisture.

In a green crop, a change in husk cover colour to yellow-brown signals that the crop is approaching harvest (as pictured below). Now is the time to get into the crop and assess the plants and cobs to help plan your harvest timing.

Plant readiness

1) Milk line

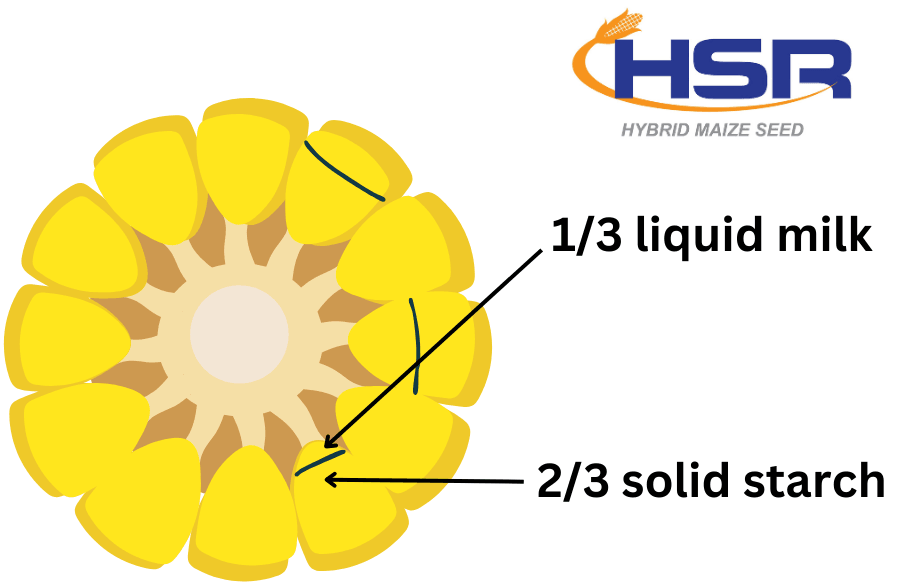

The milk line is an indication of the amount of starch present in the grain.

NOTE: The milk line is only an estimation and one factor contributing to plant readiness.

Taking a cob from a plant that is at least 20 rows into the crop and in a uniformly planted row and breaking it in half, discarding the end of the cob attached to the plant.

Remove a kernel from the broken end while holding the pointed end of the cob downwards.

While keeping the kernel the same way up as when you removed it from the cob, slide your fingernail along the length of the kernel starting at the flat end of the kernel.

Check out the point where the solid starch ends and the liquid milk begins.

If the milk line is half way down the kernel, this is what we refer to as “half milk line”.

Harvest timing is a balance between plant moisture and grain development. The milk line is an indicator of how much starch we have in our kernels; we want 100% starch fill as our goal.

Our maize agronomists have considerable experience in assessing harvest maturity.

2) Plant moisture

In some cases, a crop's dry matter percentage can be higher than the milk line suggests. Plant moisture levels can vary significantly, especially in drought-stressed crops where leaves may brown and stems may lack moisture.

To assess a plant for moisture levels, cut a section of approximately 60cm from the stalk below the cob. Twist this multiple times as though you are wringing our a cloth to see how much moisture is contained within the plant.

Moisture will vary from mildly damp feeling on your hands to being able to squeeze a steady stream of liquid.

Plant moisture = good when harvesting a crop at full starch.

3) Microwave dry matter test

Another method used to determine dry matter content, is the microwave drymatter test. Follow these steps using a standard kitchen microwave oven and digital scales that measure in grams:

Gather a representative sample of the crop (200–500g)

Cut the sample into 3-4 cm lengths, equivalent to about 100-150 grams.

Weigh the chopped crop and record the initial wet weight.

Place the sample in a microwave container with a glass of water to prevent charring.

Dry on high power for 3-5 minute intervals, recording the weight after each interval.

Turn and fluff the sample between intervals for even drying.

Reduce the drying interval as the sample nears dryness.

Once the weight stabilizes, the sample is 100% dry. Record the final dry weight.

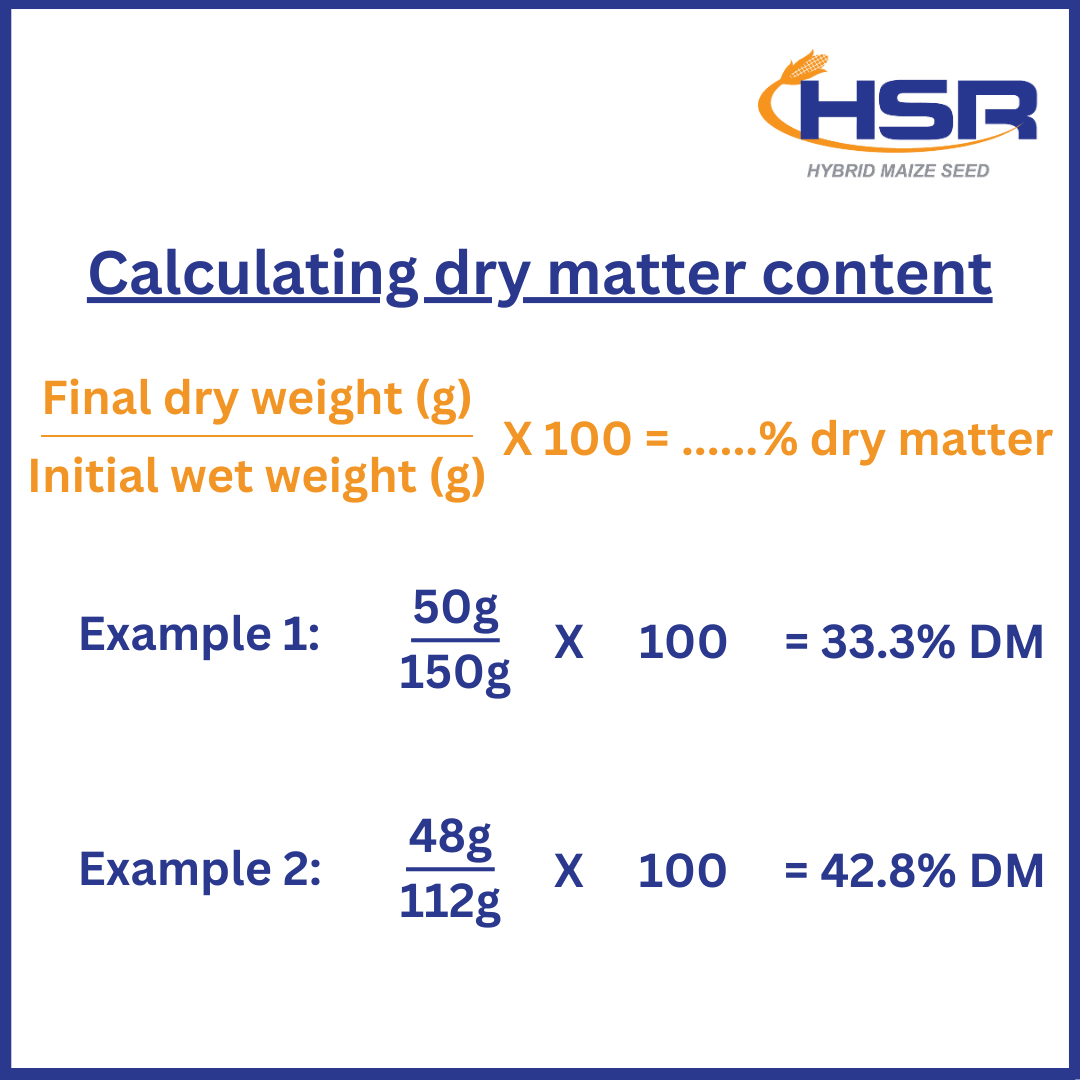

Calculate the dry matter content using the provided table.

4) Laboratory analysis

Commercial laboratories can measure the drymatter content of chopped whole plant maize samples. It will take at least three days for your samples to be processed and often considerably longer. Remember that the result of a drymatter test will only be accurate if a good representative sample is submitted.

5) Forage harvester analysis

Newer forage harvesters may have the technology to carry out a crop analysis to a laboratory standard as they harvest the crop.

The benefit of this is that the crop gets sampled multiple times and should give a more representative result.

Adjusting chop length based on moisture:

Decrease to 5-9 mm for drier silage (>38% dry matter)

Increase to 20 mm for wetter crops (<30% dry matter)

Check your chop length is right for the moisture content:

Squeeze a handful of harvested maize; your palm should feel moist. If water can be wrung out, there may be silage runoff—consider lengthening chop or delaying harvest. If compressed maize silage doesn't hold its shape post-squeeze, it's too dry; shorten chop length accordingly.

This assessment needs to be carried out in conjunction with assessing the milk line of the grain.

Using inoculant

The main purposes of using an inoculant is two-fold; firstly to reduce the pH of the silage as rapidly as possible and secondly to prevent secondary fermentation and energy loss.

Inoculants can help create a better quality forage and maximise the returns to the farmer. When choosing an inoculant it is important to select a product that delivers the maximum number of “bugs” per gram of forage.

Another consideration is to select an inoculant that can deliver a known quantity of “live bugs” to guarantee maximum performance.

Volac’s Ecosyl100 and Ecocool provide very high numbers of “live bugs” into your forage.

Ecosyl™ 100 silage inoculant is ideal for grass and legume silage. A proprietary L. plantarum strain MTD/1 works quickly and efficiently on a wide range of pH, temperature and dry matter to help make consistently better silage.

Ecocool™ silage inoculant is ideal for managing heating and aerobic spoilage of maize, grass and cereal silages. A combination of L. plantarum MTD/1 and L. buchneri strain PJB/1 drives efficient fermentation and aerobic stability.

Best practice

The best results are often achieved when a team approach is taken with the harvest operation. It is a collaboration of contractors, grower/farmer, agronomist and farm advisor. – Guy Mason

Interested in HSR Hybrids?

HSR Maize Seed is proud to be New Zealand and Australia-owned and operated.

HSR Maize Seed is available direct-to-farm through Nutrinza to bring optimum savings to farmers and contractors nationwide.